TILE MANUFACTURING

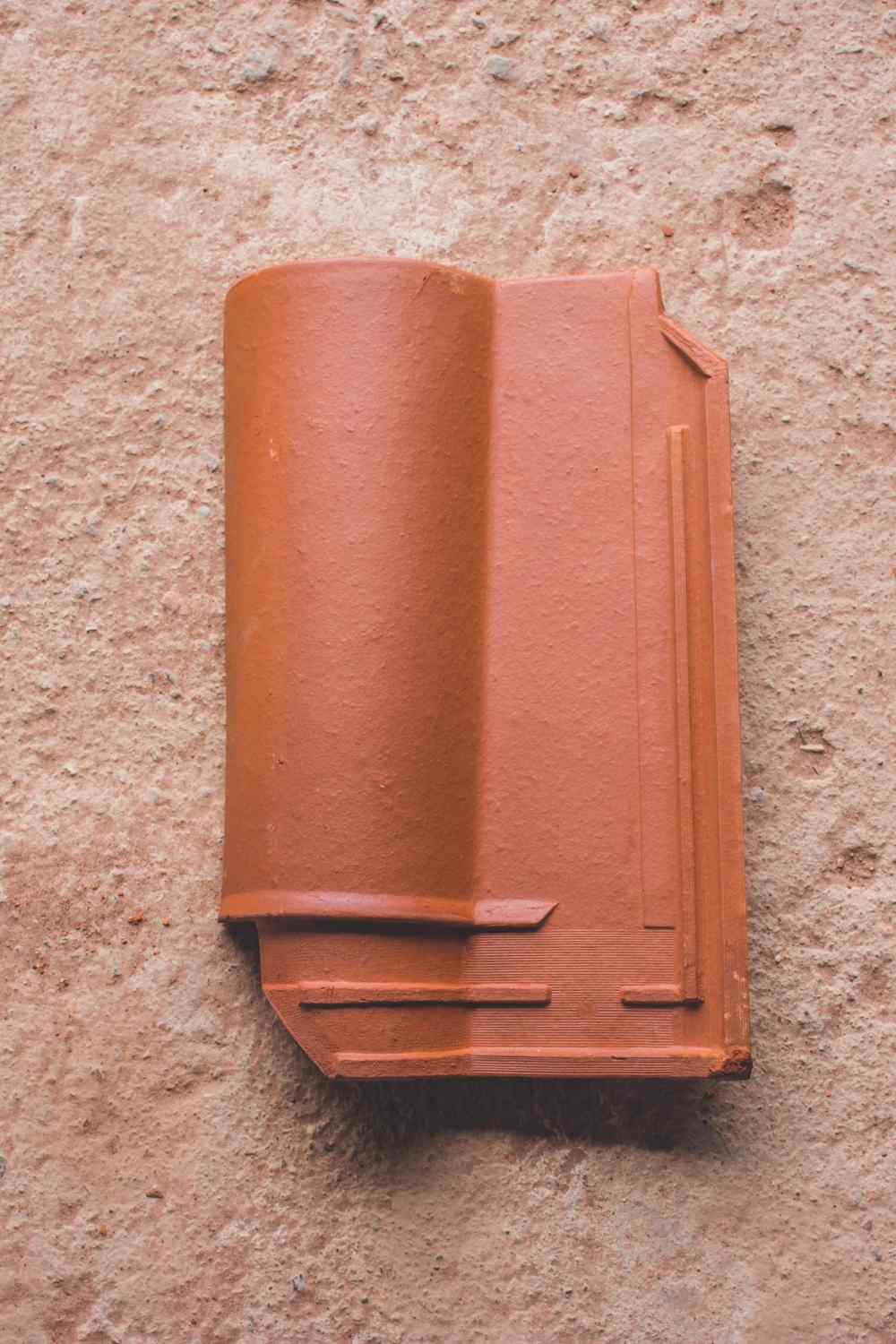

Flat tile ( Calicut tile) – Ridge tile

Euro tile – euro ridge tile

Roman tile – roman ridge tile

Awarded with SLS

No Water Absorption

100% Natural

Not Easily Breakable

Manufacturing process

Extraction – Three types of clays are extracted and collected it is mixed and kept in tanks so that the clay is well matured and of high quality

Mixing process – Three different types of clay mixtures are mixed to a standard ratio to form a suitable mixture for manufacturing.

Mixing process – Three different types of clay mixtures are mixed to a standard ratio to form a suitable mixture for manufacturing.

Cube Formation – The clay mixture is put to machine which form a cuboid that is cut into 5 consistent rectangles.

Pressing Process – The cuboid shaped clay is pressed in a mold, shaped as a tile and over here the name and the logo will be imprinted on the tile. The deformed tiles are reshaped and smoothened by using a knife to convert it to the right shape.

Drying process – The tiles are kept in racks for them to dry

Di-airing process – This process is the remove all the air molecules of the tiles

Burning Process

Quality Check

Storing of the final product.

Drying process – The tiles are kept in racks for them to dry

Di-airing process – This process is the remove all the air molecules of the tiles

Burning Process

Quality Check

Storing of the final product.

Tile Measurement

Euro Tile: Weight: 2.5-2.6 Kg Coverage: 140Sq

Roman Tile: Weight: 2.65-2.75 kg Coverage: 120Sq

Calicut Tile: Coverage (for 100 sq.ft.) 130 tiles Unit Weight 2800g ± 100g

Tile Calculator

Number Of Tiles Euro Tile Roman Tile Calicut Tile

Our people

We have provided employment to 100 people

They are given insurance and they are families are provided with proper accommodation

We maintain a friendly working environment.

Reach Us

Address:

Semuthu Tiles.

Thambarawila,

Waikkala.

Sri Lanka.

Monday to Saturday: 7am to 6pm.

Hotline: 031 – 2258500

Email : info@semuthutiles.com